When JLR announced that it would reveal the new Defender to American enthusiasts at the Los Angeles Auto Show last November, I booked my flights and hotel immediately. November can be a dreary month in New England; the stunning foliage has departed, the temperatures drop and the days grow shorter.

What a perfect time to arrive in sunny, warm Los Angeles! Just in case Brad Pitt was tied up with another project, I sprung for a new pair of Ray-Bans during an airport stopover. The songs of Randy Newman and Albert Hammond ran through my head as I anticipated the sun’s magical rays bouncing off the bonnet of the new Defender.

To quote Mr. Hammond in his song, “It pours… man, it pours.” The rain only paused briefly during the press days; the weather only improved when my plane headed east. Bummer!

Land Rover threw Hollywood-level events to launch the new Defender in North America. They provided the first chance in the US to crawl inside and explore the 2020 Defender 110, and at least view the upcoming Defender 90.

The first opportunity came the night before the Los Angeles Auto Show, when Land Rover threw a party for local and regional enthusiasts, UK visitors, US dealers and of course, celebrities. Thompson Smith, Rovers North’s Creative Director, and his wife Donna Renaud, drove from Lake Tahoe, CA; as a native Californian, Thompson would limit my social faux-pas — at least in the eyes of Californians — stretch my culinary expectations and bolster the magazine’s presence at the Auto Show.

From the UK came JLR CEO Dr. Ralf Speth, Design Chief Gerry McGovern (a 2020 OBE honoree for “services to automotive design”), Product Marketing Director Finbar McFall, and the Defender’s Vehicle Engineering Manager, Mark Wilson. A substantial presence from JLR North America included CEO Joe Eberhardt, Brand Vice President Kim McCullough, Communications Vice President Stuart Schorr and Product Manager Simon Turner.

No launch party should lack for celebrities, and Land Rover found auto enthusiasts in actors Wilmer Valderrama (Minority Report), Max Greenfield (Veronica Mars) and singers Pixie Lott and John Mayer — who even brought his Arles Blue NAS 90 SW to the event! Mayer entertained the hundreds of guests with his songs as well as his enthusiastic welcome to the new Defender. “Who is ready for a Defender in which your feet stay dry?” he asked the crowd, who roared their approval.

Land Rover’s new partnership with US Ski & Snowboard, and its sponsorship of the US Alpine Team was well represented by Lindsey Vonn and Chris Corning. Meaghan Dugan, from the US Women’s Hockey Team, and fashion executive Marcus Wainwright (Rag & Bone) also joined in the celebration. More importantly, Land Rover had reached out to West Coast and Southwest clubs and invited attendance at the event; we were delighted to see the familiar faces of Land Rover enthusiasts.

Stuart Schorr happily announced that a 22-year drought of new Defenders in North America would end this spring, and that over 700 responses had been received to view the new Defender through a new web portal. The other executives present made brief technical and marketing presentations and soon after, we were all ushered outside while the event space (pungently and appropriately named “Rolling Greens”) was converted from a presentation hall to a party room. Meanwhile, we could ogle the restored 1987 Range Rover, a “Ruta Maya” Defender 110 support vehicle, John Mayer’s Defender 90 SW, and a Discovery TReK.

Back inside, in between food and drink, you could marvel at the James Bond, No Time To Die Defenders, all showing ample signs of their roles in stunts and their status as prototypes. LEGO showed off its new Defender kit; if you wished, you could pass the time assembling it. Guests mingled around a Defender 110 and a Defender 90 before they departed for the LA Auto Show stand.

An absence of 22 years — an entire generation — injects a sort of automotive amnesia into the consumer mind. Land Rover enthusiasts kept the Defender in the public eye (as do movie producers, advertisers, video and television producers) despite the absence of new models; to us, it never left.

If we’ve not moved on, vehicle standards, consumer expectations and government safety and emissions regulations have increased at a dizzying pace. My 23-year-old Discovery I — which has the same drivetrain as an NAS Defender — features anti-lock brakes, seat belts for everyone, auto-dim rear-view mirror and a much-relaxed view of emissions and fuel mileage. That was “technology” in 1997. Safety? Remember the NAS Defender never had airbags or crumple-zones. In short, contemporary governmental regulations would not allow a “new” NAS Defender to be sold in most of Land Rover’s major markets.

I chatted with Ralf Speth, JLR’s CEO with a doctorate in Mechanical Engineering and Business Administration, about my affection for the box frame with bolt-on body panels. He stated that from every engineering principle, the monocoque design of the Defender, “with three times more torsional rigidity,” was superior. “The new Defender will exceed expectations. We cannot design for past driving conditions — we must create vehicles for the future. The Defender adds capabilities for daily driving in all on road and off-road conditions. It’s designed for not only what consumers want today, but [for what they] will want tomorrow.”

Dr. Speth spoke with evident pride that during the severe flooding last fall, “Land Rovers became the only vehicles in the UK that could traverse the flooded areas. Our Land Rover Experience team members drove pregnant women to hospitals and assisted in transporting medical professionals to clinics and hospitals.” He also spoke spiritedly about how the new Defender represents “the dynamic qualities that identify Land Rover to enthusiasts.”

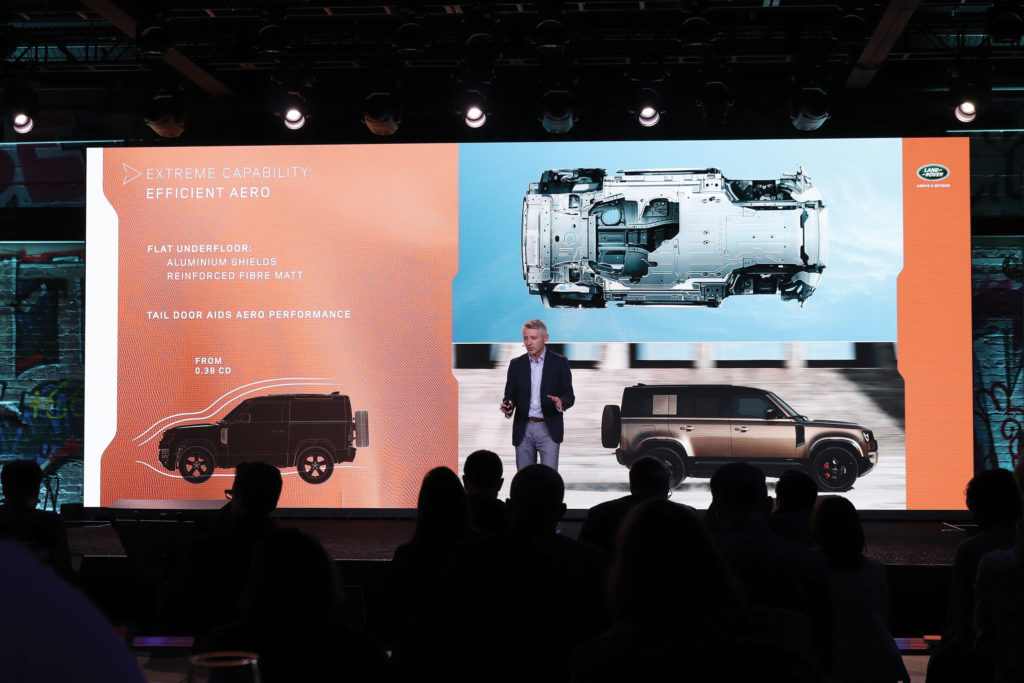

Gerry McGovern reiterated the importance of design, not as frippery or gimmick, but as the essential construct of a vehicle. “The Defender’s design must communicate what the Defender can accomplish for its owner. Its strength, capability and durability are visible in its appearance.” Every facet of the design must have functionality. “There’s a high level of design literacy in its proportions,” he said, and they exist precisely because the Defender requires approach and departure angles, ground clearance and carrying capacity that differs from the other Land Rover family model lines. It’s not all for the sake of appearance. CAFE (US) and EU fuel economy standards are helped by the aerodynamic design that drops the drag coefficient (Cd) from a billboard level of 0.59, to a sleeker 0.38.

Mark Wilson serves as the Vehicle Engineering Manager for the Defender. “Our challenge was how to replicate the off-road capabilities of the earlier Defender (we had one for testing) and improve its on road driving experience. We wanted a vehicle to go long distances anywhere, but as refinement is a modern expectation and not a luxury, it had to give the owner complete confidence on pavement at any speed.”

He explained that, “My role is to integrate the elements of the vehicle to deliver the desired results. The chassis, powertrain and electrical engineering teams all made their demands on the final design. My job was to understand where we want the car to be positioned, help set the targets, and then help deliver the car through to manufacture.”

“Once prototypes were completed, we worked with the driving test team to rectify what they uncovered, or change what they recommend. We also suggest changes to choose the best possible solutions. Again, we’re always integrating the results discovered by multiple engineering teams — how many different ways can we address an issue. I have to summarize the solutions to determine which offers the best for the vehicle.”

Even this close to introduction, Mark said, “We continue to run pre-production vehicles with lots of different drivers to replicate real world use. Many JLR staffers would be given one for a trip, whether a few days of commuting or an exploration of Scotland and Wales.”

“Our mechanical engineering was completed last June, but we continue to test them to refine any software issues, and we’ve worked closely with the manufacturing teams in Slovakia to make certain design specifications can be applied seamlessly at the plant. At the same time, our robotic test equipment runs 24/7 to search out potential problems and make necessary changes, whether to mechanical components or software.”

I expressed the concern of many enthusiasts that the inherent complexity of the new Defender might render it susceptible to problems that can’t be easily repaired in the field. Wilson was adamant, “We understand the concerns about durability — that’s not lost on the engineering teams. This Defender has to be bombproof, which is why we’ve been testing them from the Arctic Circle to the American southwest. The new test regime is far more stringent and exacting than anything we’ve done previously, from the number of tests we run to the exacting demands we place on the prototypes. Off-road capability and long-term durability are most important features to us!”

Another reason for the attention to durability is the integration of the data sent by sensors to the operation of all the running systems of the Defender. Any patches and updates must be seamless in their delivery. Mark noted, “With its over-the-air connectivity, we can deploy software anywhere and at any time. Our software also includes diagnostic tools that will run in the background, continuously informing our engineers.”

Some field “repairs” require mechanical rather than electrical tools, so I was pleased to learn that the front wings do not need a welding torch for replacement, and you can still change your own oil using gravity rather than a pump.

The new electrical platform, Electrical Vehicle Architecture (EVA 2.0), utilizes information from all the sensors and sends them to 14 computer modules. While the cameras help the driver see virtually 360 degrees around the Defender, the same camera data informs the vehicle’s transmission, engine and braking actions. The brake system activates much faster than in previous models, using a brake-by-wire setup. This means that traction control can be more precise, preventing wheel spin on slippery surfaces. Meshed fully with the new Terrain Response [which you can modify on the fly to your specific off-road needs], it adds traction at very low speeds, important for the most challenging off-road situations.

The growth in electronic platforms brought many automobile manufacturers to the CES [formerly Consumer Electronics Show] in Las Vegas last month. Thousands of software/hardware engineers, entrepreneurs and futurists examined the technology embedded in new vehicles, and Land Rover brought a Defender to the event.

To assess it, I contacted Dr. Anuja Sonalker, whose company, Steer-Tech, has created autonomous driving features for vehicle manufacturers and property owners. From her previous work, she’s recognized as an expert in automotive cybersecurity and serves on international commissions on automotive security and privacy.

She attended the CES and I asked her if she had seen the Defender and would share an assessment of Land Rover’s technical platforms. “I saw the Defender at the CES,” she said in a phone interview. “I think very highly of this new vehicle. It uses SOTIF (Safety of Intended Functionality) standards, so its sensors test constantly for ‘interfunctionality,’ to verify and validate every action of every system.” The SOTIF concept not only reacts to sensor inputs to engage the right system, but also constantly tests the entire system as a protection against its own complexity. Sonalker concluded, “In terms of automotive technology, it’s a very forward-thinking model for Land Rover. It’s very futuristic, leaps and bounds ahead in its field.”

To this enthusiast, still reckoning with a ground problem on his two-fuse Series IIA, it sounded overwhelming. Yet at the same time, that very technology that enables the Defender to climb obstacles at 2 mph will also let it hit a top speed of nearly 130 mph with equal safety and security.

As we go to press, JLR has so far only made pre-production Defenders available to drivers on specially-designed courses, like that at the 4XFAR Festival, Palm Springs, CA, last month [Full coverage in our Spring 2020 issue -ed.] We’re holding off on driving impressions until we can get significant road/off-road time with one, but I did speak some of the enthusiasts who took one with a Land Rover Driving Team Instructor on the test course. Zack Gonzales, N. Hollywood, CA, owns a ’17 Discovery Sport.

He called the Defender “rugged, but still smooth and luxurious. The cabin had high-tech features but retained the right feel for a Defender. It felt really sturdy on the course, and the air suspension clearly helped with the obstacles. How did they do that?”

Kirstin Thul, Santa Ana, CA, had spent 1,500 miles behind the wheel of her LR4 in running the Rebelle Rally last fall. After her Defender demonstration drive, she said, “I loved it! It’s a big step ahead of my LR4. It handled differently on the course, quite responsive in every condition.” Rebelle veteran Deborah Njam, Orange County, CA, summed it up perfectly, proclaiming it, “Rad,” and looking to order one.