I recently saw the “Rover Diesel” badge advertised on Rovers North’s website, a part that I have been in search of for some time. This sparked an interest, after buying and installing the badge on my 90, into the history of the diesel engine, primarily with first the Rover Company and later Land Rover LTD.

The basis of his work in engine design was to make the most efficient use of fuel. Initially, the fuel is injected at the end of the compression stroke, and the high temperature caused by this compression ignites the fuel.

When working on his calculations, Rudolf Diesel theorized that higher compression leads to higher efficiency and more power. This happens because when the piston squeezes air within the cylinder, the air becomes concentrated. Diesel fuel has a high energy content, so the likelihood of Diesel reacting with the concentrated air is greater. Another way to think of it is when air molecules are packed so close together, fuel has a better chance of reacting with as many oxygen molecules as possible. Diesel turned out to be right — a gasoline engine compresses at a ratio of between 8:1 to 12:1, while a Diesel engine compresses at a ratio of 14:1 to as high as 25:1.

Perkins Diesels of Peterborough, UK, competed at Brooklands Motor Speedway with a Diesel-powered Thomas Special chassis in 1936, recording a speed of 94.7 m.p.h. Perkins became the first company to hold 6 Diesel world speed records for a variety of distances.

In the UK, Ferguson Tractors had requested a new engine for their expanding export market and thus Standard, who were building Ferguson tractors at the time, also developed the Diesel engine for both tractor and car. The first UK vehicle to offer Diesel as an option was the Standard Vanguard in 1954, (see picture) a derivative of the Ferguson TE20 Tractor engine.

In 1954, Rover Cars Managing Director Spencer Wilks brought in Allan Botwood as the company’s first Sales Director, and Botwood seems to have seized on the idea of a diesel engine option as a way of increasing Land Rover sales. So when Rover entered discussions with Standard about a merger between the two companies in the first half of 1954, Solihull’s engineers eagerly seized on the possibility of fitting the 2.1-litre Standard diesel engine into a Land Rover. That engine was already in use for the Ferguson tractors (TE20) that Standard built under license, and it would later appear as an option in the company’s Vanguard saloons as well.

However, it quickly became clear that the Standard diesel would not fit into a Land Rover. Undaunted, in the early months of 1954 Rover and Standard set up a new joint company called Allied Motors Ltd specifically to design new engines suitable for both the tractors and the Land Rovers. How much work this company actually did, if any, is not clear. merger negotiations between the two companies

broke down in July 1954 and all cooperation ceased then. So it was probably at this point that Maurice Wilkes gave his Chief Engine Designer, Jack Swaine, the job of drawing up a new diesel engine for the Land Rover.

This task presented a whole host of problems. Rover had never designed a diesel engine before, and there was simply no expertise within the company to call on. They had certainly manufactured diesel engines, however, and were still making the Meteorite V8 and Meteor V12 engines at their Acocks Green engine plant on behalf of Rolls-Royce. But these were large-capacity engines for applications very different from the Land Rover: the Meteorite went into the Thornycroft Mighty Antar heavy haulage tractor and the Meteor into the Centurion tank.

Then there was the difficulty that Rover had nowhere to manufacture the new engine, which would demand its own machining and assembly facilities. The rapid expansion of Land Rover production over the last few years had already gobbled up all the spare factory space. On top of that was the likely cost of building new manufacturing facilities and of developing the engine. Embarking on the design and production of a brand-new diesel engine was not a step Rover could take lightly.

There were two factors that prevented the situation from becoming an impasse. The first was that the Ministry of Supply contract to build the Meteor tank engines was due to finish in late 1955 or early 1956, and this would then free up space at Rover’s Acocks Green engine plant where new engine lines could be installed. With this in mind, the Rover Board gave their approval to build the new engine at Acocks Green at their meeting on January 27, 1955 – some two and a half years before the engine would enter production.

The second factor was that Wilks and Swaine devised a strategy that involved designing the new diesel engine in tandem with a new petrol engine – which was going to be needed in a few years’ time anyway. The idea was to use a common engine design so that both engines could be machined on the same transfer line tooling, and so that parts common to both would reduce complications and simplify servicing logistics. It was a scheme that had already been used successfully by Mercedes-Benz, who had developed their 1.8-litre car diesel engine from their earlier 1.8-litre petrol engine.

Even so, Swaine decided to call in some outside help for the design of the diesel engine’s combustion chamber, and the company he worked with was Ricardo Engineering. That company’s Comet V combustion chamber design was incorporated into the production engines. However, the basic architecture of the engines was Swaine’s own work, and he chose to use pushrod-operated overhead valves with a chain-driven camshaft – a configuration that was becoming popular at the time. Both petrol and diesel engines would have a three-bearing crankshaft and roller cam followers instead of the pad type which had proved so prone to wear in Rover’s IOE petrol engines. The petrol engine would have a single carburetor, and the diesel would have Pintaux-type injection nozzles along with a mechanically-governed CAV injection pump. Although the two engines would need different cylinder heads, the careful design allowed the block castings to be very similar indeed: the location for the distributor drive on the petrol engine, for example, doubled as the location for the fuel distribution pump on the diesel.

To guard against problems of premature bore wear, Swaine played for safety. He made sure the diesel would have adequate cooling by using a “wet-liner” design, where the bores had removable liners (for ease of replacement) which had coolant circulating all around their outsides. The petrol engine would not need such extreme protective measures, and by omitting the liners it was possible to use larger-diameter pistons which would give the engine better performance. This is why the diesel engine started life with a swept volume of 2 litres (2052cc) while the petrol engine would be introduced with a 2.25-litre capacity (2286cc).

There was one additional requirement in the design of the diesel engine, and that was to ensure that its power and torque outputs were as close as possible to those of the existing 2-litre petrol engine. The thinking behind this was that Rover wanted to avoid the need for designing new transmission components for the diesel models: if these could use the same ones as the petrol engine, cost and complication on the assembly lines could be avoided. Swaine and his team got close enough to the petrol engine’s outputs for the strategy to work, although the diesel was always a lower-revving engine and its torque was considerably poorer than that of the petrol engine.

As Rover needed the new diesel engine before the new petrol engine, development of the latter lagged some way behind. The first prototype diesels were probably ready by the end of 1955, and the first Land Rovers with them itr took to the roads in March and April 1956. In the meantime, it had become clear that the new OHV engines were an extremely tight fit in the Land Rover’s engine bay and that in some circumstances the front axle could foul the sump and the cooling fan could foul the radiator. The simplest way around this was to move the front cross-member and the radiator mounted on it forwards by an inch and to move the front axle forwards by two inches. Thus, the 86” Series I became the 88” and the 107” became the 109”. These wheelbases continued for the duration of the Series I,II and III up to 1984 and the introduction of the 110 and 1984 for the 90.

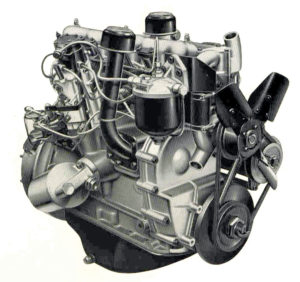

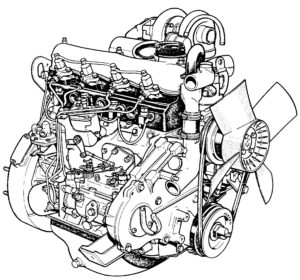

2-litre diesel engine, 1957-1961

Rover’s aim in designing its first diesel engine was to minimise the need for changes elsewhere in the Land Rover. The engine had to suit the existing transmission components and offer similar overall performance to the 2-litre petrol engine already in production.

The new engine was designed so that its basic configuration would also be suitable for a petrol engine that would eventually replace the existing IOE four-cylinder, and designer Jack Swaine chose a modern short-stroke configuration with overhead valves. The cast-iron block was fitted with “wet” cylinder liners and the combustion chambers were designed in conjunction with Ricardo Engineering to suit an indirect injection fuel system.

These first Land Rover diesels were very noisy engines, and early examples often suffered from cracked cylinder heads. While power was similar to that of the 2-litre petrol engine, torque was very much poorer and consequently, acceleration was sluggish. Fuel economy was also not much better than that of the contemporary Land Rover petrol engine.

- Dimensions: 2052cc, 85.7mm bore x 88.9mm stroke

- Compression ratio: 22.5:1

- Fuel system: Indirect injection with CAV pump

- Power and torque: 51bhp at 3500rpm and 87 lb-ft at 2000rpm

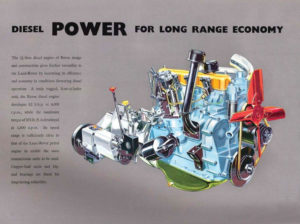

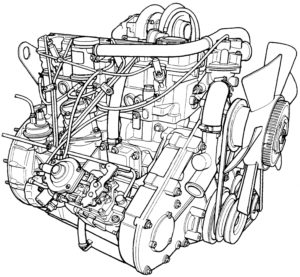

2.25-litre Diesel engine, 1961-1980

The original 2-litre Land Rover diesel was replaced by a more powerful 2.25-litre version when the Series IIA models were introduced in October 1961. This had the same bore and stroke dimensions as the contemporary four-cylinder petrol engine and, unlike the original 2-litre diesel, did not have “wet” cylinder liners. It once again had three main bearings, and the cylinder blocks were painted Light Admiralty Grey.

Like the 2.25-litre petrol engine, the “two-and-a-quarter” diesel earned a reputation for longevity and reliability, although – once again – fuel economy and road performance were not among its strengths. It was used throughout Series IIA production, in the Series IIA and IIB Forward Controls, and for the first nine years of Series III production.

Other versions of the engine were built for marine use, and some went into Russian Volga cars used as taxis in Belgium. Note that early engines were rated according to the optimistic SAE standards (UK Society of Auto Engineers), and that later engines were re-rated in accordance with the stricter DIN 70020 standard (German Institute Standard), thus giving the appearance that they had been de-tuned.

- Dimensions: 2286cc, 90.47mm bore x 88.9mm stroke

- Compression ratio: 23:1

- Fuel system: Indirect injection with CAV pump

- Power and torque: 62bhp at 4000rpm and 103 lb-ft at 1800rpm

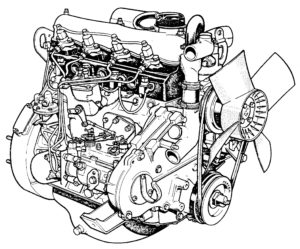

2.3-litre diesel engine, 1980-1984

Like the petrol engine, the four-cylinder diesel was re-engineered with a five-bearing crankshaft for the 1981 model-year. It was introduced in August 1980 for the 88-inch Series III models, and became available in 109-inch types that November.

This engine was used in the final Series III models and in the first One Tens. As with the five-bearing petrol engines, Its block was always painted Terra Cotta Red to aid identification. Land Rover generally referred to it as the 2.3-litre diesel engine although, like its petrol equivalent, it retained the original 2286cc swept volume.

Other versions of the engine were used in taxis and by Coventry Climax.

- Dimensions: 2286cc, 90.47mm bore x 88.9mm stroke

- Compression ratio: 23:1

- Fuel system: Indirect injection with CAV pump

- Power and torque: 60bhp at 4000rpm and 130 lb-ft at 1800rpm (One Ten engines)

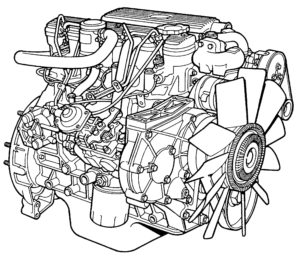

2.5-litre Diesel engine, 1984-1992

The next stage in the evolution of the original OHV diesel engine was a stretch to 2.5 litres with a longer stroke that brought an extra 7bhp but, strangely, less torque than before. On these engines, a belt drive for the camshaft replaced the chain drive of the earlier diesels.

The revised engine was introduced in January 1984 for the One Ten models and was also used in the Ninetys which arrived in June 1984. In most markets it was replaced during 1990 by the 200Tdi turbocharged diesel engine, but the naturally-aspirated 2.5 diesel remained available for another couple of years in the newly-renamed Defender models to meet some large fleet orders, for some overseas markets and also Military contracts.

Versions of this engine were also used in Freight Rover vans (15J prefix) and in FX4R Taxis (20J prefix with manual gearbox and 21J with auto).

- Dimensions: 2495cc, 90.47mm bore x 97mm stroke

- Compression ratio: 21:1

- Fuel system: Indirect injection with DPS pump

- Power and torque: 67bhp at 4000rpm and 114 lb-ft at 1800rpm

2.5 Turbo Diesel engine, 1986-1989

A further evolution of the 2.5 NAD Engine was to increase the torque and to improve its power to compete with the 4 X 4 competition of the mid-1980’s, this was called project “Falcon”. To achieve this Nimonic exhaust valves, Teflon coated pistons, oil jets for the crankshaft journal, 8-blade viscous fan and integrated oil cooler in the radiator were all added to withstand the extra stresses and temperature stresses that fitting a Garrett Turbocharger added to the basically similar 2.5 engine. After its introduction the sales of Land Rover 90 & 110 were boosted (sorry about the pun), it was more fuel efficient and powerful than its predecessor. One of its early problems was oil being sucked into the air cleaner from the breather system, causing the engine to run on the engine oil causing catastrophic failures (damaged blocks, overheating, etc.), this was corrected with a new breather systemto longevity. A few of these were also fitted into crop sprayers of the day.

- Dimensions: 2495 c.c., 9047mm bore x 97mm stroke

- Compression Ratio: 21.0:1

- Power and Torque: 85 hp at 4250rpm and 150 ft-lbs at 1800rpm

2.5 200 Tdi Engine (commonly known as the Gemini engine) 1989 – 1994

With the steady improvement of Land Rover sales came a slightly better investment in new products and thus power units, especially the launch in 1989 of the Range Rover based Discovery, called Project Gemini, with the all new 200 Tdi, so called as it had 188 ft lbs of torque, 200 being the nearest rounded up number. It was a completely redesigned engine, with alloy cylinder head, a new Bosch direct injection system, strengthening ladder frame between the engine block and the oil sump, plus using the piston tops for the combustion chamber. The lessons learned from the Turbo Diesel engine, mainly overheating and oil being sucked from the breather system into the air filter, causing, in some instances, the engine to keep running on engine oil after the fuel supply had been turned off were applied to this newly designed engine, using a sealed breather system. This was the biggest leap forward for Land Rover since the inaugural 2.0 litre Diesel, way back in 1957.

This engine was designed to be fitted all Land Rover models, including the newly badged Defenders, Range Rovers plus the recently launched Discovery. The Discovery quickly became Europe’s top selling 4 X 4 and these engines are still popular today, noted for their simplicity and, if maintained correctly, longevity. During the early ‘90’s, Land Rover offered factory prepared kits for retro fit of the 200 Tdi into the Range Rover, to replace both V8’s and the sometimes troublesome 2.4 and 2.5 VM Diesels, plus from 2.5 Petrol, 2,5 NAD and 2.5 TD in the 90/110 Defenders.They were quite costly, though for all new components, a worthwhile investment if the vehicle was to be kept for some time. One of the drawbacks of the 200 Tdi was the 2 different formats used in production, the Defender and Discovery/Range Rover

had inlet/exhaust manifold/Turbo and different front covers fitted, thus duplicating spare parts for in-service maintenance and, in time, conversion complications from either Natural Aspirated Diesels or Petrol powered 90/110’s plus the V8’s in Range Rover Classics and Series vehicles.

The UK MoD declined the 200 Tdi in favour of the 2.5 NAD as the front cover could not be adapted to be fitted with the somewhat large 24v generator for the military radios fitted inside the rear of the Land Rover.

Nevertheless, a non-complex, reliable and capable 2.5 litre and still sought after engine for Land Rover enthusiasts as a conversion in either Turbo or Non-Turbo formats. Its reputation for being a reliable power unit was such that a variety of manufactures also used it in their builds, crop sprayers being one of many outlets for this popular engine.

- Dimensions: 2495cc, 90.47mm bore x 97mm stroke

- Compression ratio: 21:1

- Fuel system: Direct injection with DPS pump

- Power and torque: 107 bhp Defender and 111 bhp Discovery and Classic Range Rover 188 lb-ft

These were also popular with crop sprayers (Agribuggy) and various other light commercial users.

2.5 300 Tdi Engine 1994-2005 Factory line fit (commonly called the Wolf engine) 1994-2006

The 300 Tdi is probably the most popular of any Land Rover Diesel engine, being fitted across the whole range of vehicles, 90, 110, 130 Defenders plus the Range Rover Classic (1994-95) Discovery I (1994-1998?) a feat only matched by the long running V8 petrol engine (1970-1994).

The development from the 200 to 300 Tdi refined the idle speed and vibration, the designation of 300 is the Foot Pounds of torque or Newton Meters (actually 195 ft lbs 264 NM), though still modest, the idle proved to somewhat more stable. The fuel pump, brake servo pump, engine block and many other components were developed especially for the 300 Tdi, as Land Rover were at last showing a profit and thus funds were available for development.

After a shaky start, due to some timing belts wandering off the crankshaft timing gear, cured by a modification kit that kept the belt aligned correctly, the 300 Tdi has proved to be a stalwart power unit, provided it is maintained and serviced correctly. Many have recorded over 500,000 miles ( 805,000 kms)!

Improved engine and transmission mounts have helped achieving this, along with further development on the Bosch injection pump.

The ladder frame used on the 200 Tdi Engine was deleted, a standard front cover was fitted, thus the basic version of the engine could be fitted to Range Rover/Discovery and the Defender. The space used for A/C on all applications could now be used for the MoD’s 24v Generator, thus the Truck Utility Medium (TUM) for 110’s and Truck Utility Light (TUL) for the 90’s, See attached leaflet.

Land Rover again offered full conversion kits for Classic Range Rover V8’s, Defender V8’s, 2.5 NAD/TD/200Tdi, even offering an auto kit. See attached leaflet.

Modifications were made during its life to comply with E.U. Emissions Regulations, up to its replacement, firstly by the Land Rover developed TD5 (1998) and then Ford’s 2.4 Puma engine (2005). It was possible to Special Order the 300 Tdi upto 2005 as an alternate to the TD5, also contracts – including the Ministry of Defence called for the 300 Tdi, so these contracts needed to be satisfied. Over its life time over 1 million 300 Tdi’s engines were built by Land Rover. During this time, Ford in Brazil were fitting licensed 300 Tdi engines to the Ford Ranger pick-up, made by International as the Maxion engine. This was developed into an HS 2.8 engine with a variable vane turbo, with great success.

Rovers North now offers an upgrade kit from the standard 300 Tdi to the HS 2.8 spec engine, please see the attached graph or the comparison of boost and torque This kit contains all the necessary components to upgrade a standard 300 Tdi to the HS 2.8, including pistons and Variable Vane Turbo.

Incidentally, BMW bought the Rover Group, including Land Rover in 1994, selling Land Rover off to Ford in 2000, so the writing was on the wall, Ford wanted their engines fitted to Land Rover products, the days of the 300 Tdi factory fit were numbered!

- Dimensions: 2495cc, 90.47mm bore x 97mm stroke

- Compression ratio: 21:1

- Fuel system: Direct injection with DPS pump

- Power and torque: 111 bhp at 4000rpm and 195 lb-ft

To many enthusiasts, the Land Rover diesel of any vintage became the pinnacle for off-road use because of its torque at low rpm and its lack of an ig- nition system. The sacrifices for on-road use (lower top speed, leisurely acceleration, and higher decibel level) seemed well worth it then, and continue today.